Product Details

Product Details

Product Specification

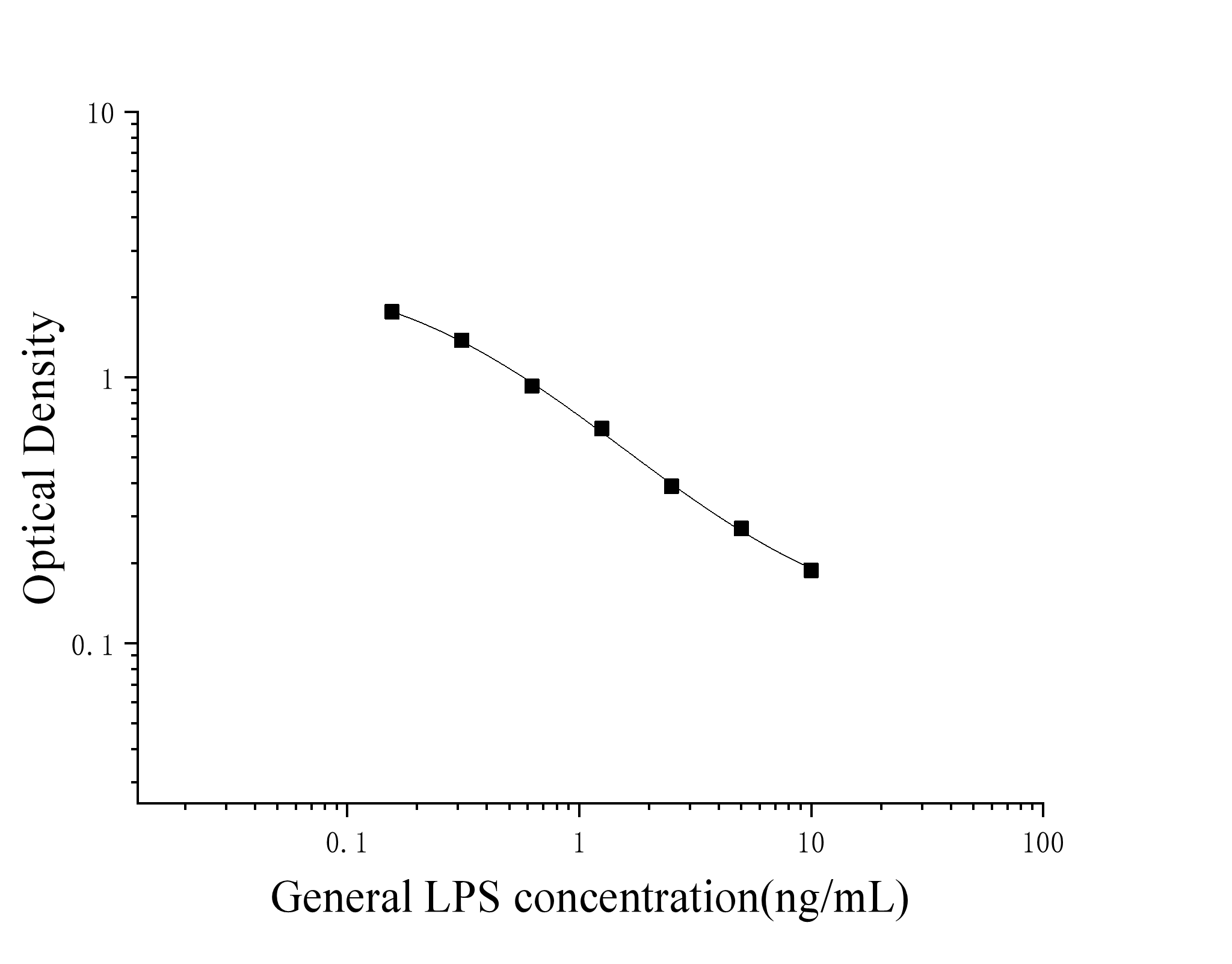

| Usage | I. Required Equipment: 1. Microplate reader (450nm) 2. High-precision pipettes and pipette tips: 0.5-10uL, 5-50uL, 20-200uL, 200-1000uL 3. 37°C incubator 4. Distilled or deionized water II. Sample Preparation and Requirements: The detection range of the kit is not equivalent to the concentration range of the analyte in the sample. Before the experiment, it is recommended to estimate the analyte concentration in the sample based on relevant literature and conduct a pilot experiment to determine the actual concentration in the sample. If the analyte concentration in the sample is too high or too low, dilute or concentrate the sample appropriately. If the sample type is not listed in the instructions, it is recommended to conduct a pilot experiment to verify the validity of the test. Serum: Collect whole blood in a serum separator tube at room temperature for 2 hours or at 2-8°C overnight. Centrifuge at 1000×g for 20 minutes and remove the supernatant. Alternatively, store the supernatant at -20°C or -80°C, but avoid repeated freezing and thawing. Plasma: Collect the sample using EDTA or heparin as an anticoagulant. Centrifuge at 1000×g for 15 minutes at 2-8°C within 30 minutes of collection. Remove the supernatant and test. Alternatively, store the supernatant at -20°C or -80°C, but avoid repeated freezing and thawing. Tissue homogenate: Rinse the tissue with pre-chilled PBS (0.01M, pH 7.4) to remove residual blood (lysed red blood cells in the homogenate may affect the test results). Weigh the tissue and mince. Add the minced tissue to the appropriate volume of PBS (generally a 1:9 weight-to-volume ratio, e.g., 1g of tissue sample to 9mL of PBS. The specific volume can be adjusted according to experimental needs and recorded. It is recommended to add protease inhibitors to the PBS) in a glass homogenizer and grind thoroughly on ice or in a homogenizer. To further lyse the tissue cells, the homogenate can be sonicated or repeatedly freeze-thawed. Finally, centrifuge the homogenate at 5000×g for 5-10 minutes and remove the supernatant for analysis. Cell Culture Supernatant: Centrifuge at 1000×g for 20 minutes. Remove the supernatant and analyze it immediately, or store it at -20°C or -80°C, but avoid repeated freeze-thaw cycles. Cell Lysis Buffer: Adherent cells are gently washed with pre-chilled PBS, then trypsinized and harvested by centrifugation at 1000×g for 5 minutes. Suspension cells can be directly harvested by centrifugation. Wash the collected cells three times with pre-chilled PBS and resuspend in 150-200 μL of PBS per 1 × 10^6 cells (protease inhibitors are recommended; if the cell count is very low, the PBS volume can be reduced appropriately). Disrupt the cells by repeated freeze-thaw cycles or sonication. Centrifuge the extract at 1500 × g for 10 minutes at 2-8°C, and remove the supernatant for testing. Other biological samples: Centrifuge at 1000 × g for 20 minutes, and remove the supernatant for testing. Sample Appearance: The sample should be clear and transparent, and suspended matter should be removed by centrifugation. Sample Storage: Samples collected for testing within one week can be stored at 4°C. If testing is not possible, aliquot the sample into a single-use aliquot and freeze at -20°C (for testing within one month) or -80°C (for testing within six months). Avoid repeated freeze-thaw cycles. Hemolysis of the sample can affect the final test results, so hemolyzed samples are not suitable for this test. III. Sample Dilution Scheme: Please estimate the sample concentration range in advance. If your test sample requires dilution, the reference dilution scheme is as follows: 100-fold dilution:One-step dilution. Add 5 μL of sample to 495 μL of universal diluent for a 100-fold dilution. 1000-fold dilution:Two-step dilution. Add 5 μL of sample to 95 μL of universal diluent for a 20-fold dilution. Then, add 5 μL of the 20-fold diluted sample to 245 μL of universal diluent for a 50-fold dilution, for a total dilution of 1000-fold. 100,000-fold dilution:Three-step dilution. Add 5 μL of sample to 195 μL of universal diluent and dilute it 40-fold. Then, add 5 μL of the 40-fold diluted sample to 245 μL of universal diluent and dilute it 50-fold. Finally, add 5 μL of the 2,000-fold diluted sample to 245 μL of universal diluent and dilute it 50-fold, for a total dilution of 100,000-fold. For each dilution step, the sample volume should be at least 3 μL, and the dilution factor should not exceed 100-fold. Mix thoroughly during each dilution step to avoid foaming. IV. Pre-Test Preparation: 1. Remove the test kit from the refrigerator 10 minutes in advance and equilibrate to room temperature. 2. Prepare a gradient standard working solution: Add 1 mL of universal diluent to the lyophilized standard. Let stand for 15 minutes to completely dissolve, then gently mix (concentration 10 ng/mL). Then dilute to the following concentrations: 10 ng/mL, 5 ng/mL, 2.5 ng/mL, 1.25 ng/mL, 0.625 ng/mL, 0.3125 ng/mL, 0.15625 ng/mL, and 0 ng/mL. Serial dilution method: Add 500 μL of universal diluent to each of seven EP tubes. Pipette 500 μL of the 10 ng/mL standard working solution into the first EP tube and mix thoroughly to make a 5 ng/mL standard working solution. Repeat this procedure for subsequent tubes. The last tube serves as a blank well; there is no need to pipette liquid from the penultimate tube. See the figure below for details. 3. Preparation of HRP-antigen working solution: 15 minutes before use, centrifuge the concentrated HRP-antigen at 1000×g for 1 minute. Dilute 100× concentrated HRP-antigen to a working concentration of 1× with universal diluent (e.g., 10 μL concentrate + 990 μL universal diluent). Prepare immediately before use. 4. Preparation of 1× Wash Buffer: Dissolve 10 mL of 20× Wash Buffer in 190 mL of distilled water. (Concentrated Wash Buffer removed from the refrigerator may crystallize, which is normal. Allow to stand at room temperature until the crystals have completely dissolved before preparing.) V. Procedure: 1. Remove the desired strips from the aluminum foil bag after equilibration at room temperature for 10 minutes. Seal the remaining strips in a ziplock bag and return them to 4°C. 2. Sample Addition: Add 50 μL of sample or standard of varying concentrations to the corresponding wells. Add 50 μL of Universal Diluent to the blank wells. Follow this with 50 μL of HRP-Antigen Working Solution to each well. Cover with film and incubate at 37°C for 60 minutes. (Recommendation: Dilute the sample to be tested at least 1x with universal diluent before adding it to the ELISA plate for testing. This will reduce the impact of matrix effects on the test results. The final calculation of the sample concentration should be multiplied by the corresponding dilution factor. It is recommended to set up duplicate wells for all samples to be tested and standards.) 3. Washing: Discard the liquid and add 300 μL of 1x wash buffer to each well. Let it stand for 1 minute. Shake off the wash buffer and pat dry on absorbent paper. Repeat this process 5 times (a plate washer can also be used for washing). 4. Adding substrate: Add 90 μL of substrate (TMB) to each well, cover with sealing film, and incubate at 37°C in the dark for 15 minutes. 5. Adding stop solution: Remove the ELISA plate and add 50 μL of stop solution directly to each well. Immediately measure the OD value of each well at a wavelength of 450 nm. VI. Calculation of Experimental Results: Result Interpretation: 1. Calculate the average OD value of the standard and sample replicates and subtract the OD value of the blank well as the correction value. Plot the standard curve of the four-parameter logistic function on double-logarithmic graph paper, with concentration as the horizontal axis and OD value as the vertical axis. 2. If the sample OD value is higher than the upper limit of the standard curve, dilute the sample appropriately and retest. Multiply the sample concentration by the corresponding dilution factor.  VII. Kit Performance: VII. Kit Performance:1. Repeatability: Intra-plate coefficient of variation (CV) less than 10%, inter-plate coefficient of variation (CV) less than 10%. 2. Recovery: LPS was spiked into selected healthy serum, plasma, and cell culture supernatant at three different concentrations, and the recovery was calculated.

|

||||||||||||

| Dilution ratio | Recovery rate (%) | Serum | Plasma | Cell culture supernatant | |||||||||

| 1:2 | Range | 83-95 | 88-96 | 90-110 | |||||||||

| Average recovery rate | 91 | 92 | 96 | ||||||||||

| 1:4 | Range | style="width: 20.042%; height: 22px;">89-10487-108 | 105-115 | ||||||||||

| Average recovery rate | 93 | 98 | 110 |

| Name | 9 6 T Configuration style="height: 10px; width: 29.98%; text-align: center;" width="29.9800%">Remarks | |

| Pre-coated 96-well enzyme plate | 8 holes×12 strips | None |

| Standard | 2 bottles | Dilution according to the instructions |

Universal diluent |

2×20mL |

None |

Concentrated HRP-antigen |

60uL |

|

20× washing solution |

2×10mL |

Dilution according to the instructions |

Substrate (TMB) |

10mL |

None |

Stop solution |

6mL |

None |

Sealing film |

4 sheets |

None |

Instructions |

1 portion |

none |

2. Improper plate washing may result in inaccurate results. Ensure that all liquid in the wells is aspirated thoroughly before adding substrate. Do not allow the wells to dry out during incubation.

3. Remove any residual liquid and fingerprints from the bottom of the plate, as this will affect the OD value.

4. The substrate developer solution should be colorless or very light in color. Do not use substrate solution that has turned blue.

5. Avoid cross-contamination of reagents and specimens to prevent erroneous results.

6. Avoid direct exposure to strong light during storage and incubation.

7. Do not expose any reagents to bleaching solvents or the strong fumes emitted by bleaching solvents. Any bleaching agent will destroy the biological activity of the reagents in the kit.

8. Do not use expired products, and do not mix components with different product numbers and batches.

9. Recombinant proteins from sources other than the kit may not be compatible with the antibodies in this kit and will not be recognized.

10. If there is a possibility of disease transmission, all samples should be managed properly and samples and testing devices should be handled according to prescribed procedures.